In today’s fast-paced world of manufacturing, shipping, and e-commerce, packaging plays a much larger role than just containing products—it protects, preserves, and represents your brand. And when it comes to corrugated boxes, strength matters. The Box Compression Tester from Pacorr is the ideal solution to ensure your packaging performs when it matters most.

From preventing product damage to meeting international standards, compression testing has become an essential part of the packaging process. Let’s explore how Pacorr’s Box Compression Tester helps you stay ahead of the curve.

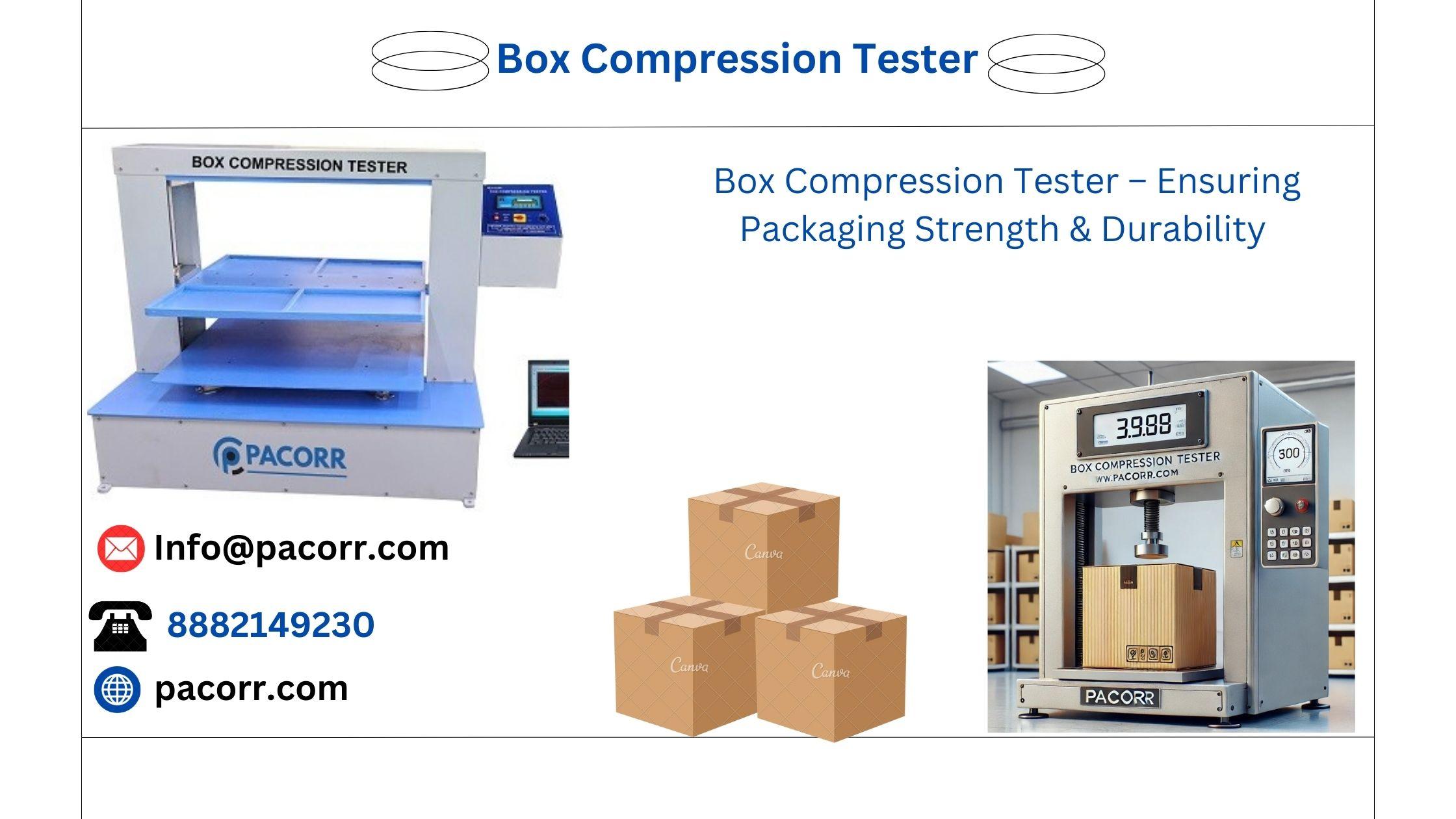

What is a Box Compression Tester?

A Box Compression Tester (BCT) is a specialized machine used to determine how much vertical pressure a corrugated box can withstand before collapsing. It mimics the conditions boxes experience during stacking in storage or transit, allowing manufacturers to evaluate the true strength and durability of their packaging.

Whether you're testing retail cartons or bulk shipping boxes, a BCT provides the data needed to optimize packaging materials and protect goods during handling and delivery.

Why is Compression Testing Important?

Every box that enters the supply chain is exposed to stacking, jostling, and pressure. If your packaging can’t hold up, the consequences are serious: damaged products, returns, lost revenue, and unhappy customers.

Compression testing gives you the confidence to ship with peace of mind. It ensures that your packaging meets the strength requirements for its intended use—and doesn’t fail when pressure builds up.

Key Benefits:

-

🛡 Prevents Collapse and Damage – Ensure your boxes can handle stacking and storage.

-

💸 Reduces Packaging Costs – Avoid over-packaging while maintaining strength.

-

📈 Improves Warehouse Efficiency – Stack with confidence, save on space.

-

🌍 Meets Global Standards – Comply with ASTM, ISO, and TAPPI testing protocols.

-

🤝 Builds Customer Trust – Products arrive in perfect condition, every time.

Pacorr’s Box Compression Tester: Built for Reliability

At Pacorr, we understand that precision and performance are key. Our Box Compression Tester is engineered with advanced technology and robust construction to deliver dependable results every time.

Key Features:

-

📊 Digital Control Panel – Get instant, real-time readings for force and deformation.

-

🏗 Heavy-Duty Frame – Built to handle long-term, high-pressure testing.

-

⚙️ Microprocessor-Based Controls – Ensures accuracy and consistency.

-

📦 Adjustable Test Platform – Suitable for boxes of various dimensions.

-

✅ Compliance with Global Standards – ASTM D642, ISO 12048, and TAPPI T804.

It’s the perfect tool for quality control labs, production facilities, and packaging R&D teams.

How Does Box Compression Testing Work?

The process is simple but highly effective. A box is placed between two compression plates. The top plate descends gradually, applying vertical force. The test continues until the box collapses or reaches its maximum resistance. The machine captures key data, including the force applied and the deformation that occurs.

What You Learn:

-

📦 Maximum compressive load

-

📉 Displacement at peak pressure

-

📋 Deformation curve under stress

-

📐 Safe stacking limits for warehouse use

These results provide a reliable foundation for packaging improvements and supply chain safety.

Industries That Trust Compression Testing

Compression testing isn’t just for packaging companies. It’s essential for any industry that uses boxed packaging:

-

🛒 E-Commerce – Keep products safe through multiple shipping stages.

-

🍽 Food & Beverage – Protect perishables during bulk transport.

-

💊 Pharmaceuticals – Ensure packaging can hold up under cold storage or extended transit.

-

💻 Electronics – Secure fragile items with strong, tested packaging.

-

🏭 Industrial Goods – Validate heavy-duty packaging for equipment and parts.

No matter the sector, box strength matters—and testing it makes all the difference.

Why Choose Pacorr?

At Pacorr, our mission is to help businesses deliver quality through precision testing. With years of experience in developing industrial testing equipment, we’ve built a reputation for excellence and trust.

Here’s Why Businesses Choose Us:

-

🔧 Tailored Solutions – Machines can be customized for your specific needs.

-

🧠 Expert Support – From installation to training, our team is with you every step.

-

🔍 High Accuracy Sensors – Get consistent, reliable results.

-

⏱ Quick Turnaround – Fast delivery and responsive service.

-

🌐 Global Reach – Pacorr machines are used by brands around the world.

We don’t just sell machines—we provide solutions that add value to your operations.

Best Practices for Effective Testing

To get the most accurate results from your Box Compression Testing:

-

Calibrate regularly to ensure accuracy.

-

Use new, undamaged samples for each test.

-

Position the box correctly between compression plates.

-

Conduct multiple tests for consistent averages.

-

Record and review your data for ongoing improvements.

Compression testing isn’t just about one box—it’s about long-term reliability.

Final Thoughts

When it comes to packaging, strength isn’t optional—it’s essential. Weak boxes cost time, money, and reputation. But with Pacorr’s Box Compression Tester, you can eliminate uncertainty and take control of your packaging quality.

Whether you’re launching a new product or reviewing your current packaging strategy, Pacorr gives you the tools to deliver better, stronger, and more reliable packaging.

🔗 Explore the full range at Pacorr.com and request your quote today.

Let’s make your packaging smarter—and stronger—together.